After disassembling and shredding consumer household appliance scraps contains amounts of valuable products ,

1.Plastic scraps e.g. acrylonitrile butadiene styrene (ABS), PS, polypropylene (PP) and polyethylene (PE) ;

2.Printed circuit boards (PCB)

3.Mix Ferrous & Non-Ferrous Metals (As ferrous , Alloy copper brass aluminum scraps) , Stainless steel scraps and insulated wire

Typical Consumer household appliances divided into three types:

* small appliances; (consumer E-waste refers to the reprocessing and re-use of old Electric and Electronic waste Equipment widely known as WEEE or e-scraps ))such as toasters, coffee makers, and blenders ,Consumer phones telecommunications equipment,Electrical and electronic tools Toys, leisure and sports equipment Medical devices Monitoring and control instruments Automatic dispensers

* major appliances, or white goods also known as a large domestic appliance or large electric appliance or simply a large

appliance, large domestic, such as stoves, cookers, refrigerators, freezers, tumble driers, dishwashers, air conditioners , washers, dryers , microwaves ,DVD players, stereos,

* consumer electronics, or brown goods. such as TVs, computers, radios, printers,computers, or games consoles.

Typical stages of metal separation in e-waste and Appliances recycling process after crushing

1. primary removal of ferrous metals using overband magnets or pulley magnetic drum .

2. ferrous metal-free fraction pas onto Eddy Current Separator (ECS) for copper aluminum precious non-ferrous metals recovery

3. Following Eddy Current Separator , ultra-high strength magnetic or Induction Sensor Sorter working for weakly magnetic fragmented or shredded stainless steel separation from the mixture scraps ,also enables to separate the printed circuit boards (PCBs) scraps

Magnetic separation Devices

a wide variety of powerful Rare Earth Magnetic Separators to capture and hold ferrous and weakly magnetic stainless steel from the mixture

Eccentric Eddy current separator

1.High Intensity Eccentric & Concentric Eddy Current Separator for scraps nonferrous

2.Ultra High Frequency UHF ECS for micro-fine nonferrous particles recovery

Induction Sensor Sorter

normally for the waste that separated by the non-ferrous separator to recover rest of stainless steel and insulation wire etc

Air separation machine

for pre-treatment of dusty material --

a light fraction capable of flight, known as the shredder light fraction (SLF)

Trommel screen

or rotary screen, is a kind of mechanical screening machine widely used in the separation operation. to controls the

material separation by the particle size

Belt conveyor

the conveyor system could be customized strictly according customer`s working side .

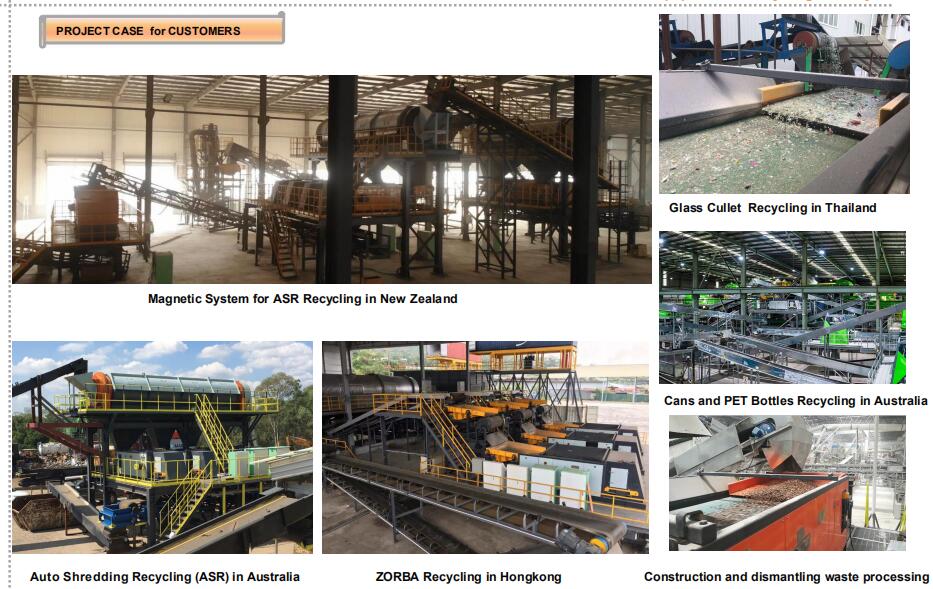

Customer Photos

OTHER INDUSTRIAL MAGNET SEPARATION TECHNOLOGY SERVED IN 1.AUTOMOBILE SHREDDING & SCRAP METAL PROCESSING,such as Car bodies ,Mixed scrap, Aluminum Can Recycling 2.ADVANCED METAL Automotive white goods RECOVERY & SORTING ,such as Engine blocks ,Aluminium rims and profiles ,etc ALUMINUM/alumina SHREDDING & SORTING 3.WASTE TO ENERGY Power Plants for maximizing metal extraction from the incineration bottom ash 4.MUNICIPAL SOLID WASTE RECYCLING 5.E-SCRAP RECYCLING 6.ferromagnetic and Nno-ferrous metals recycling in steel mills and foundries Applications 7.Food, Chemical, Pharmaceuticals 8.Lumber/ Waste wood processing

9. Mining/Minerals 10.Quarry/Aggregate

Company Profile

About us

This was in 2004, when our founder, Bingxun Wang, first used the magnetism knowledge to make research and designed the first set eccentric pole eddy current separator in China. Thus we are fully aware of this responsibility in sorting resources field for nonferrous metal. In the year 2006, with 25 years magnetic experience Ejet Magnet Established, Keeping improvement for all kinds of magnetic separators, to provide high quality and high performance products is our own responsibility, moreover, to offer the best solution and the most effective service is one of higher-standard targets we are pursuing. Ejet has strict quality control system for raw materials inspection, producing quality inspection and machine testing. With 4 members team in the beginning, Ejet has grown through continuous product innovation and worldwide expansion to over a 5000 square feet of manufacturing space and more than 100 employees. The main products eddy current separator , magnetic separator, induction sorters and AI technology machine for recycling industries had been export to more than 50 countries. Materials testing and machines OEM could be available for better solutions of metal recycling, plastic, glass cullet, construction waste, incineration bottom ash, Aluminum, E waste recycling. Also for food, chemical, lithium batteryindustries. Ejet after sales service promise that within 15miniutes we will make response to customer’s consolations. On condition that some problems cannot be solved by calls or call videos, engineers are available to serve overseas.

FAQ

1.Q:are you Original Manufacturer ?

A:Yes

2.Q: Which machine /system should I choice for ?

A:To guarantee the good performance , please kindly provide as details information as possible about the material ,

e.g. where is the material come from ? whats the main components and the percentage ?size range , productivity