eddy current aluminum separators streamline the recovery and separation of conductor from galss cullet

Product Description

|

eddy current non-metallic conductors metal separators are wildly used in recovery and separation aluminum, die-cast metal, copper and other value metals from nonmetallic material.

Maily usage for aluminum/copper magnetism separator:

1. Recovery aluminum cans from plastic and glass bottles.

2. High efficiency of recovery of aluminum from city waste.

3. Separation of nails and iron steels from crushed machines.

4. Recovery of valuable metals from glass cullet.

|

|

eddy current conductors separator is useful in situations such as:

- Separation of non-ferrous metals in auto shredder residue

- Separation of non-ferrous metals from solid waste incinerator ash

- Sorting of aluminium beverage cans from non-magnetic recyclables

- Removal of non-ferrous contamination from crushed glass cullet

- Separation of non-ferrous dross from foundry sand

- Non-ferrous metal removal in WEEE recycling plants

- Removal of aluminum components in UPVC window recycling

- Separation of non-ferrous metals from wood waste

- Separation of non-ferrous metals from plastics

- Separation of non-ferrous metals from electronic scrap

- Separation of non-ferrous metals from car recycling applications

Standard Features and Benefits for alternating magnetism metal separator:

- NdFeB permanent magnet , powerful magnetic field

- Import main parts:Nord Gear Motor,NSK Bearing,Seigling Belt,Schneider Electric

- The best separation effect could be achieved by adjustable rotor position

- Reduce belt long-term wear from ferrous build up

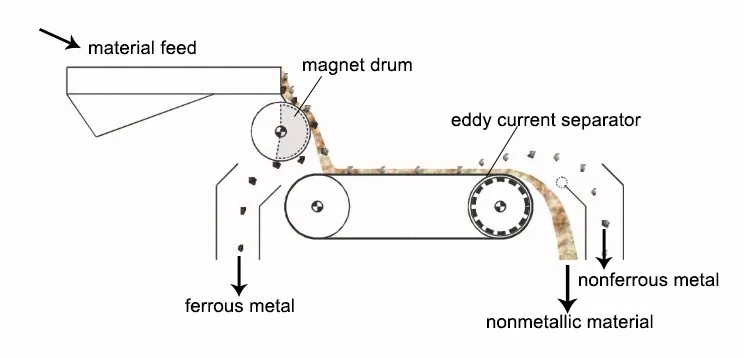

Working principle

Important: When looking at an Eddy current separator, the waste travelling over the magnetic must be in a thin layer to allow the magnetic perform to its best, in case processed metal waste is mixed with ferrous metal. The Ideal format for any metal separation is first magnetic ferrous discharge, onto a vibration conveyor to spread out and further separate the remaining metals to allow the Eddy current magnetic to work at its optimal efficiency.

In order to give you the responsible quotation, pls kindly inform us the following details:

1. What kind of material you are going to deal with?

2. What’s the granularity of the material?

3. What’s the producing capacity you are going to achieve?

we can design and manufacture complete eddy current conveyor systems or simply furnish eddy current drums or any other piece of magnetic separation equipment to meet your requirements.such as:

1.eddy current nonferrous metal magnetic separator

2.permanent and electric magnetic separator

3.wet and dry type magnetic separator

4.Permanent magnet and electromagnetic lifting equipment

5.magnetic drum

6.chute magnetic separator

7.magnetic sweeper

8.magnetic cartridges(rods or tubes)

9.Belt conveyor

10.screening

11.vibrating feeder

12.air classifier